Rebar cutting is a precision operation which has no leeway to go wrong. During construction, sticking to the design by the engineer is extremely important – which makes it equally important to use rebars exactly as depicted in the drawings. The real issue arises when the workers have to decide between using electric or hydraulic rebar cutters. While both get the job done well, there is the concern for accuracy which confuses them. So, electric or hydraulic rebar cutter: which is better? Read on for some insights.

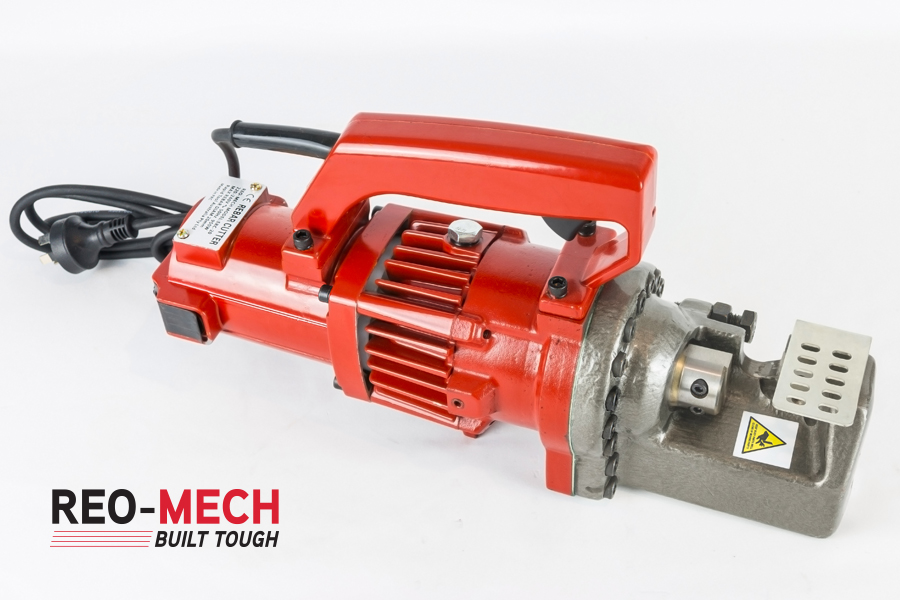

Electric rebar cutters

The first selling point of electric rebar cutters is that they are fast, but up to what extent. If your design requires cutting of many bars and the project is rushed, you will do better with an electric rebar cutter. These cutters are also known for a smooth cut finish. This allows for achieving high accuracy in construction as per the engineer’s design. Since the rate of cutting is high, one can expect a reduction in the man-hours the workers employ in cutting bars.

Hydraulic rebar cutters

The greatest advantage of using hydraulic rebar cutters is that they can achieve cuts along any axis. If your design requires the rebar to be cut longitudinally (along its length), you can achieve that by using a hydraulic rebar cutter. The thing to note about in rebars is that they increase in strength along with increase in diameter. The pattern on the rebar also gives it some strength. This requires different power to cut through rebars of different cross-sections – which is possible in a hydraulic rebar cutter. You can vary the amount of hydraulic pressure being applied to achieve smooth and efficient cuts on bars of all cross sections.

Seeing how both the rebar cutters are head to head in the competition, it is best to judge which one you would need as per the jobs needed to be done on your construction site. Choose wisely.